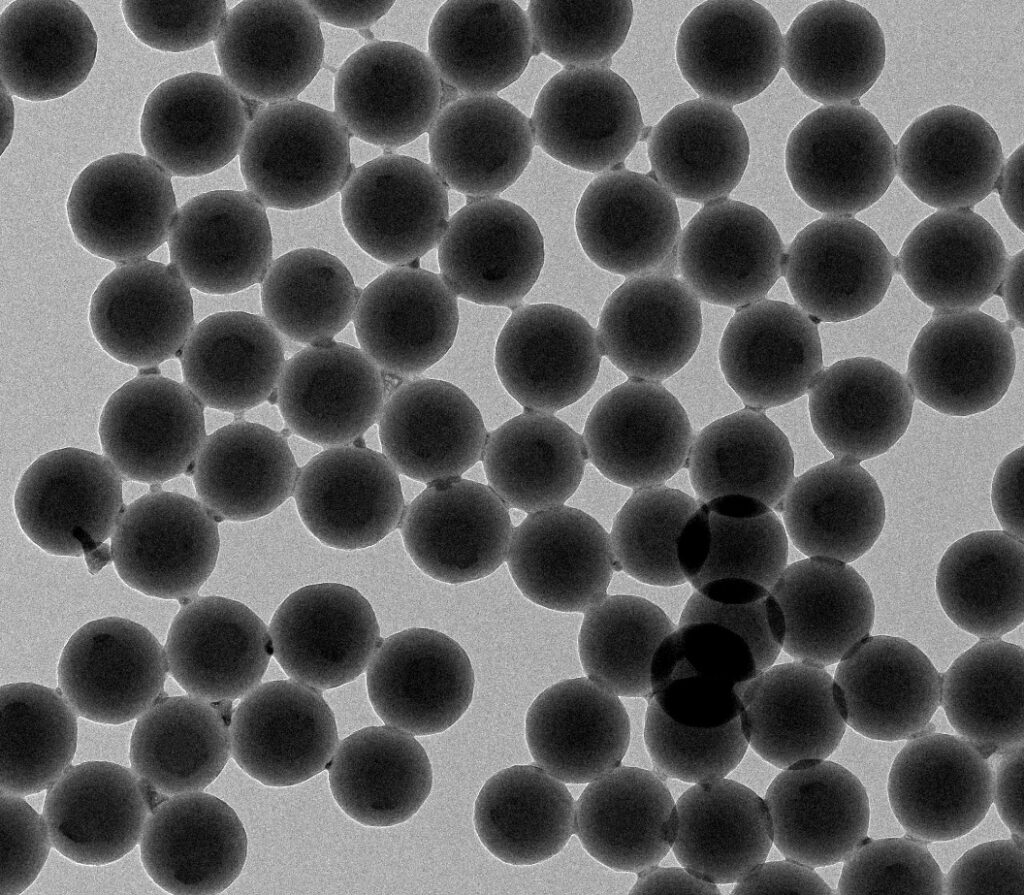

Microspheres, as the name suggests, are small spherical particles in the micrometer range (1-1000 microns). They have various applications in medicine and life sciences, such as drug delivery, tissue engineering, biosensors, medical imaging, etc.

01Classification

It can be classified according to their composition, structure, and function. Some common types include:

Polymer Microspheres:

They are made of natural or synthetic polymers such as gelatin, alginate, poly(lactic-co-glycolic acid) (PLGA), and polyethylene glycol (PEG). They can be used to encapsulate drugs, proteins, or DNA molecules for controlled release or targeted drug delivery.

Ceramic Microspheres:

They are made of inorganic materials such as hydroxyapatite (HA), silicon, and calcium phosphate. They can be used to simulate the mineral phase of bone tissue or enhance the mechanical strength of scaffolds.

Lipid Microspheres:

They are made of lipids such as phospholipids, cholesterol, and triglycerides. They can form vesicles or emulsions and carry hydrophilic or hydrophobic substances. They can also deliver genes or vaccines by fusing with cell membranes.

Magnetic microspheres:

They are made of magnetic materials, such as metal oxides such as iron, cobalt, and nickel. They can be manipulated by an external magnetic field and used for separation, concentration, or transport of biomolecules. They can also be used for magnetic resonance imaging (MRI) or hyperthermia therapy.

Hollow microspheres:

They have a hollow core and a thin shell. They have a higher specific surface area, lower density, and better flowability than solid microspheres. They can also be used to load more drugs or contrast agents for enhanced delivery or imaging.

02 Properties

It’s properties depend on a variety of factors, such as particle size, shape, surface charge, porosity, and biodegradability. These properties can affect their interactions with biological systems and their performance in various applications.

(1) Particle size

The size of it can affect their diffusion, sedimentation, and biodistribution. Smaller microspheres can penetrate deeper into tissues and organs, while larger microspheres can avoid being cleared by the reticuloendothelial system (RES).

(2) Particle shape

The shape of it affects their encapsulation, flow, and mechanical stability. Spherical microspheres can have higher packing density and lower friction coefficients, while irregularly shaped microspheres can have higher surface areas and better adhesion.

(3)Surface charge

The surface charge of it determines their electrostatic interactions with biomolecules and cells. Positively charged microspheres can bind to negatively charged cell membranes or DNA molecules, while negatively charged microspheres can repel them. Neutral microspheres can have minimal interactions with biological components.

(4)Porosity

The porosity of it can easily affect their drug loading capacity, release rate, and degradation rate. Porous microspheres can hold more drugs or biomolecules than non-porous microspheres. However, porous microspheres can also release their contents faster and degrade faster than non-porous microspheres.

(5)Biodegradability

It’s biodegradability can affect their biocompatibility and elimination from the body. Biodegradable microspheres can be broken down into harmless products by enzymes or hydrolysis, while non-biodegradable microspheres can exist in the body for a long time. Biodegradable microspheres are more popular in drug delivery and tissue engineering applications.

03 Synthesis methods of microsphere

- Spray drying: This is a method for preparing solid or hollow microspheres by atomizing a liquid solution or suspension into fine droplets and drying it in hot air. This method is simple, rapid and scalable. It can be used to encapsulate drugs, proteins or DNA molecules for controlled release or targeted drug delivery.

- Emulsion polymerization: This is a method for preparing polymer microspheres by dispersing monomers in a continuous aqueous phase and initiating polymerization using a water-soluble or oil-soluble initiator in the presence of a surfactant. This method can produce uniform and stable microspheres with high yield and low cost. It can also incorporate drugs or biomolecules into microspheres during or after the polymerization reaction.

- Sol-gel method: This is a method for preparing ceramic microspheres by hydrolyzing and condensing metal alkoxides or nitrates in a solvent to form a colloidal suspension or gel, and then drying and calcining the gel. This method can produce porous and biocompatible microspheres with controllable size and shape. It can also be used to modify the surface of microspheres with functional groups or biomolecules.

- Extrusion method: This is a method for preparing lipid microspheres by extruding a lipid solution or suspension into an aqueous phase through a small nozzle under high pressure to form solidified droplets. This method can produce spherical and smooth microspheres with narrow particle size distribution and high encapsulation efficiency. It can also change the composition and properties of lipid microspheres by changing the lipid type, concentration and temperature.

- Coprecipitation method: This is a method for preparing magnetic microspheres by mixing metal salt solution and alkaline solution to form insoluble metal hydroxides precipitated into fine particles, and then coating the particles to obtain polymers or surfactants. This method can produce magnetic microspheres with high magnetization and stability. Now new technologies have also been derived to prepare microspheres, such as microfluidics. Interested friends can learn about it by themselves.

04 Some Applications:

1.Drug delivery: Microspheres can be used to deliver drugs to specific parts of the body, such as tumors, infections or inflamed tissues. They can also control the release rate and duration of drugs, improve the efficacy of drugs and reduce their side effects. For example, PLGA microspheres can deliver anticancer drugs to brain tumors by crossing the blood-brain barrier. Lipid microspheres can deliver insulin to diabetic patients by oral administration. Magnetic microspheres can deliver drugs to liver tumors.

2.Tissue engineering: Microspheres can be used to create scaffolds or matrices that support cell or tissue growth and differentiation. They can also provide mechanical, chemical, and biological cues to regulate cell behavior and function. For example, HA microspheres can be used to create bone tissue scaffolds with osteoconductive and osteoinductive properties. Alginate microspheres can be used to encapsulate stem cells or growth factors to promote cartilage tissue regeneration. Hollow microspheres can be used to create lightweight and loose scaffolds for soft tissue engineering.

3.Biosensors: Microspheres can be used to enhance the sensitivity and specificity of biosensors that detect biomolecules or pathogens. They can also amplify signals or change the color of biosensors. For example, polymer microspheres can be used to immobilize antibodies or enzymes on the surface of biosensors for immunoassays or enzyme assays. Ceramic microspheres can be used to create optical biosensors, where they change their refractive index or fluorescence when stimulated by an analyte. Magnetic microspheres can be used to separate and concentrate biomolecules or pathogens for biosensor detection.

4.Imaging: Microspheres can be used to improve the contrast and resolution of imaging techniques for tissue or organ structure or function. They can also label or track cells or drugs in vivo. For example, lipid microspheres can be used as ultrasound contrast agents to enhance the acoustic scattering of sound waves. Hollow microspheres can be used as X-ray contrast agents to increase the attenuation of X-rays. Magnetic microspheres can be used as MRI contrast agents to change the relaxation of water molecules’ magnetic resonance.

Microspheres are versatile and multipurpose particles with a variety of applications in medicine and life sciences. They can be customized for different needs and purposes by changing their type, properties, synthesis method, and usage. Compared with traditional materials or methods, it have many advantages, such as higher efficiency, lower toxicity, better biocompatibility, and easier operation. However, they also bring some challenges, such as potential immunogenicity, aggregation, degradation, clearance, etc. Therefore, further research and development are needed to optimize their design and performance and to ensure their safety and effectiveness.